Andritz AG is an international company based in Austria that provides technology solutions and engineering services across various industries. The company is particularly recognized in the following areas:

– Energy Production: Equipment and systems related to renewable and non-renewable energy generation.

– Pulp and Paper Industry: Technologies required for producing paper and wood products.

– Food Industry: Processing and production solutions for food products.

– Oil and Gas Industry: Provision of equipment and services related to this sector.

Andritz Pumps

Andritz has extensive experience and expertise in manufacturing industrial pumps, particularly in the oil and gas sector. These pumps are generally divided into two main categories:

a) Centrifugal Pumps

These pumps are designed for high-capacity and high-speed liquid transfer. Key features include:

– High Performance: Suitable for transferring liquids at various temperatures.

– Efficient Design: Reduces energy consumption and operational costs.

– Versatile Applications: Includes the transfer of crude oil, petroleum products, and chemical liquids.

b) Positive Displacement Pumps

These pumps are designed for transferring high-density and high-viscosity liquids. Features include:

– Ability to Handle Viscous Liquids: Suitable for substances such as asphalt and heavy raw materials.

– Precision Measurement: Allows for accurate flow control.

– Suitable for Harsh Conditions: Resilient in challenging operational environments such as high pressure and temperature.

Applications of Andritz Oil Pumps

Andritz pumps are widely used in the oil and gas industry:

– Refineries: For transferring crude oil, petroleum products, and chemical liquids.

– Tankers: In the transportation of liquids.

– Extraction Projects: For moving liquids during extraction processes.

Advantages of Using Andritz Pumps

– High Quality: Designed and manufactured according to international standards.

– Technical Support: Strong after-sales service and technical assistance.

– Innovation: Utilization of advanced technologies to enhance efficiency and reduce costs.

Andritz Company offers a variety of centrifugal pumps specifically designed for the oil and gas industries. These pumps are engineered to meet the demanding requirements of this sector, ensuring efficiency and reliability. The main types of centrifugal pumps related to the oil and gas industries include:

1. End-Suction Pumps: These are commonly used for transporting crude oil and other liquids. They are designed for easy maintenance and high efficiency.

2. Split Case Pumps: Known for their durability and high flow capacity, split case pumps are ideal for applications requiring large volumes of liquid, such as in refinery processes.

3. High-Pressure Pumps: These pumps are designed to handle high-pressure applications, making them suitable for transporting fluids in various stages of oil and gas extraction and processing.

4. Multi-Stage Pumps: These pumps are used when high pressure is required. They consist of multiple impellers, allowing them to achieve higher pressures than single-stage pumps.

5. Specialized Pumps: Andritz also develops customized centrifugal pumps tailored to specific applications within the oil and gas sector, including pumps for handling corrosive or viscous fluids.

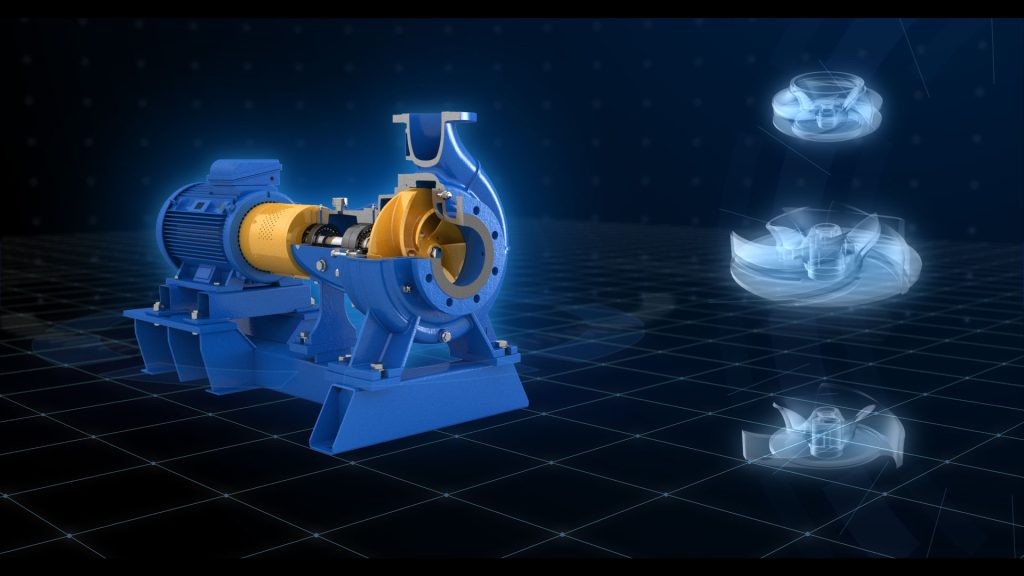

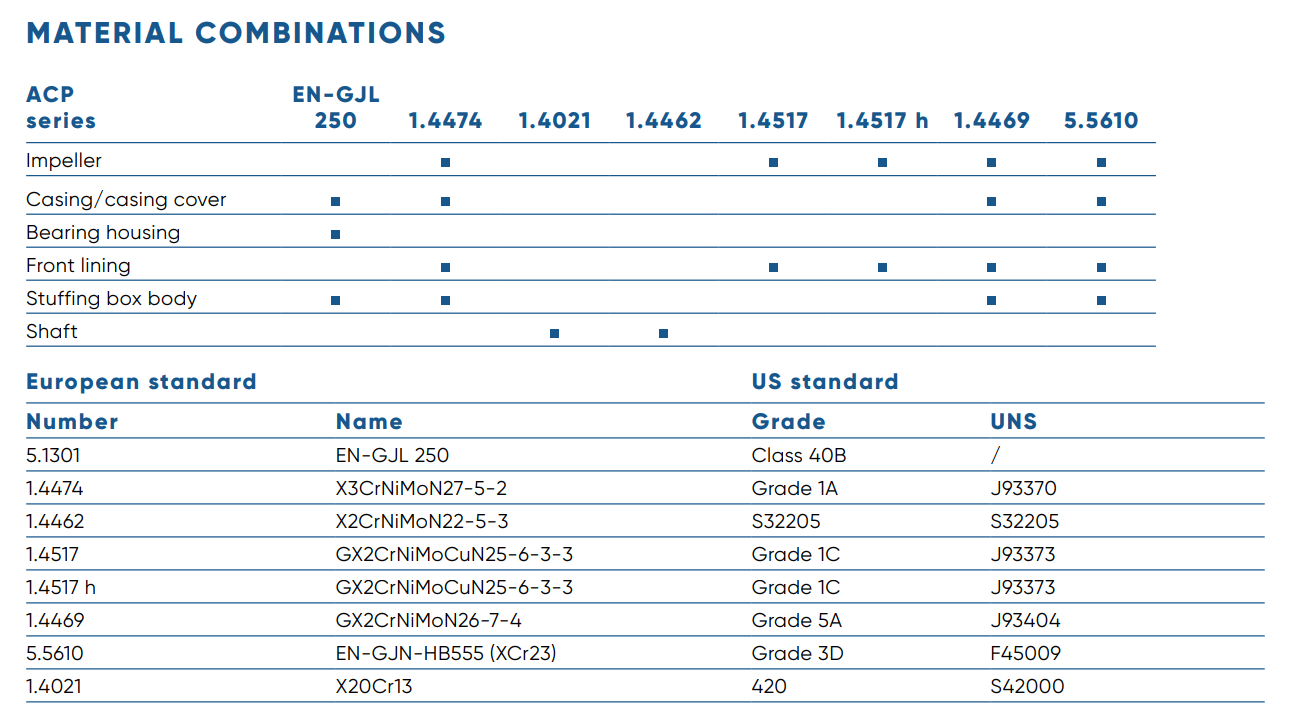

Single-stage centrifugal pumps

ANDRITZ single-stage centrifugal pumps from the ACP are available in a highly wear-resistant, open impeller design. Thanks to their low axial thrust and open channels, these pumps are suitable for conveying many different media. Depending on the impeller design, they can convey slightly contaminated and contaminated media with some solids and content with consistencies of up to 8%. Equipped with our innovative SMARTSEP degassing system an additional separation impeller acts as an integrated degassing system and removes gas from the media and conveys fibers reliably back to the pump at the same time. Thus, no additional vacuum pump is needed. The controlling of the degassing valve becomes very easy. When the pump is running the valve is open, but when the pump is not running the valve is closed.

ANDRITZ ACP pump series

| Design: | single-stage, single-flow, open impeller |

| Consistency: | up to 8% |

| Head: | up to 190 m |

| Flow rate: | up to 9,000 m³/h |

| Pressure: | up to 40 bar |

| Temperature: | up to 200° C |

| Efficiency: | up to 90% |

Product benefits

- Maximum efficiency of up to 90%

- State-of-the-art NPSH behavior

- Part load behavior better than industry benchmark

- SMARTSEP degassing system

- Reduced number of spare parts to be held in stock

BEARING SUPPORT

• Single casting with

integrated lantern

• Only seven bearing support

sizes for the entire series

SHAFT

• Ensures minimum shaft

deflection and low

mechanical vibration

TOUGH BEARINGS

• Long service life

SHAFT SEALING

• Single mechanical seal

for stock conveyance

without sealing and

rinsing water

• Double mechanical seal

• Dynamic seal

IMPELLER DESIGN

• Open, semi-open or closed

• Special impeller for tomato

paste and fruit concentrate

WEAR LINING

• One wear lining to protect

the pump casing

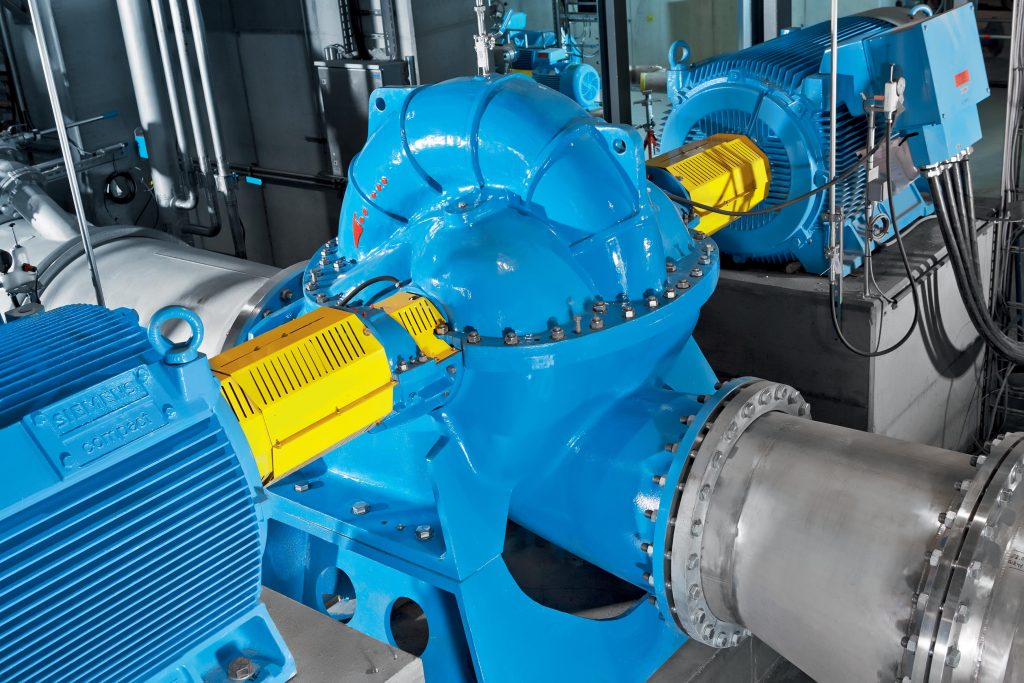

Split case pumps

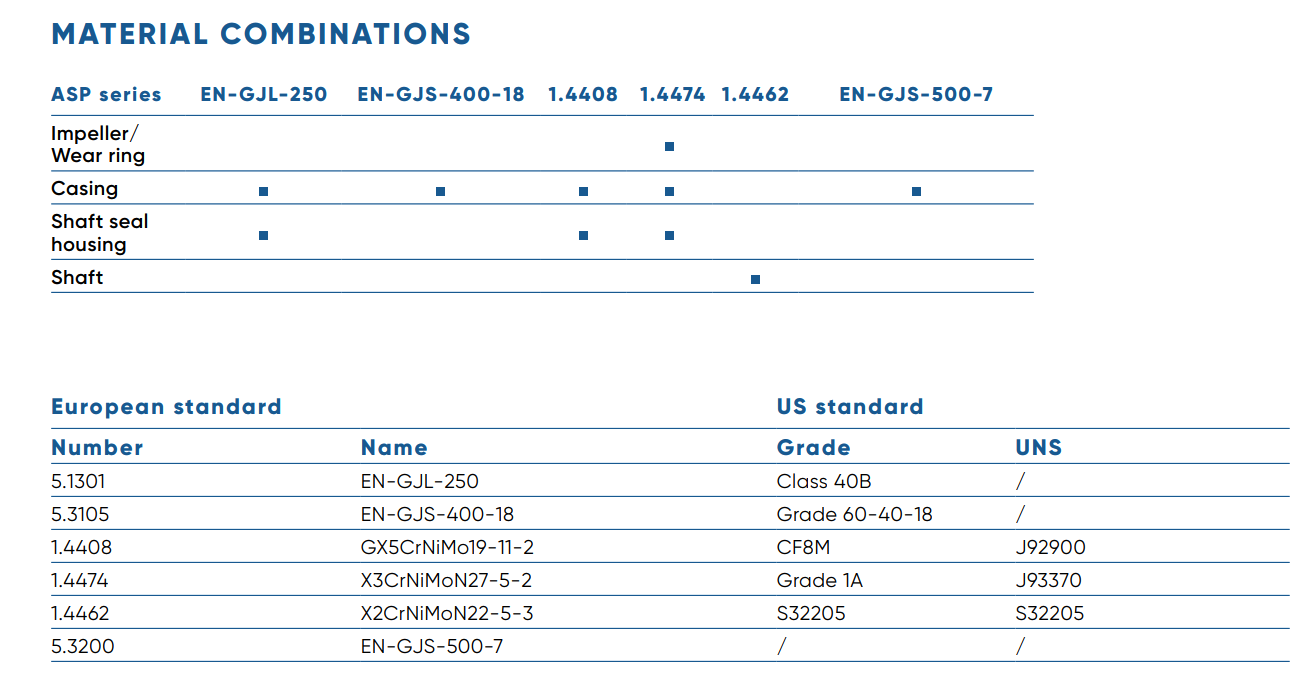

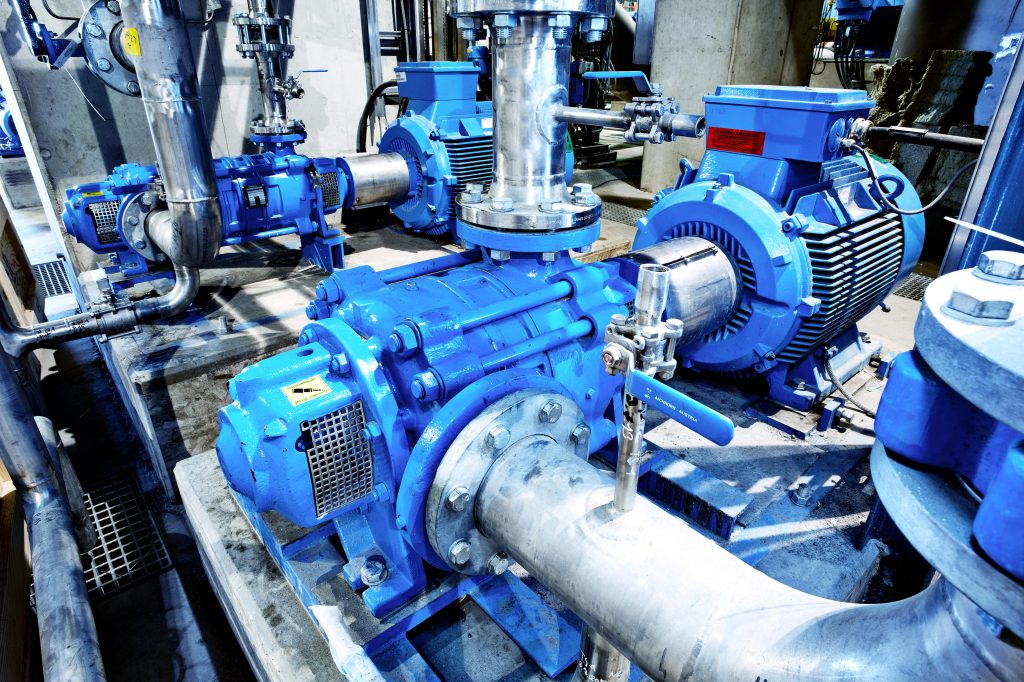

ANDRITZ split case pumps from the ASP series meet the highest customer demands in terms of efficiency, long service life, maintenance friendliness, and economy. With efficiencies of over 90%, they help to save valuable energy. All pumps are fitted with a double-flow radial impeller which achieves very favorable NPSH values. Due to the axial split case design, maintenance is fast and easy. Designed with a double-flow radial impeller and in-line casing, the pump can be horizontally or vertically installed (with horizontal installation, the motor can be placed on the left or right).

| Design: | single-stage, axial split case |

| Consistency (P&P industry): | up to 2% |

| Head: | up to 250 m |

| Flow rate: | up to 40,000 m³/h |

| Pressure: | up to 25 bar |

| Temperature: | up to 80° C |

| Power: | up to 7,000 KW |

Product benefits

- Energy savings

- Highest efficiency (above 90%)

- Low pulsation

- Horizontal split casing

- Easy and fast maintenance

- Excellent NSPH values

SEALING SYSTEMS

• Stuffing box

• Single or double

mechanical seal

• Cartridge seal

• Split seal for short maintenance times

• Replacement of seals without

dismantling the casing

SPLIT VOLUTE CASING

• Sealing of the upper and lower

parts with O-rings ensures short

maintenance times

DOUBLE SUCTION IMPELLER

• Efficiency of up to 91%

• Impeller with or

without staggered blades

(according to specific design)

• For P&P, low pulsation impeller

with staggered blades

SHAFT BEARING FOR OIL

OR GREASE LUBRICATION

• Compact and robust bearing

ensures ease of installation

and long life

SECOND SHAFT END

• For flexible choice of drive side

• Provided as standard

CONNECTION FLANGE

• According to DIN, ANSI, mating-

flange with polishing on demand

PEDESTAL/LEGS

• Flexible and easy pump mounting

• Foundation with motor available

on request

High-pressure pumps, MP series

The high standard of the ANDRITZ multi-stage high-pressure pumps from the MP series is based on decades of experience in designing hydraulic machines and on extensive process know-how. The pumps are installed for conveying clean and slightly contaminated media such as cold and hot water, condensate, deionized water, oils, and suspensions.

ANDRITZ MP pump series

| Design: | multi-stage, closed impellers |

| Head: | up to 950 m |

| Flow rate: | up to 400 m³/h |

| Pressure: | up to 100 bar |

| Temperature: | up to 160° C |

| Power: | up to 600 kW |

Product benefits

- Horizontal design with a closed impeller and external bearing assemblies on both sides

- Axial heat expansion by the pump rotor is absorbed internally without influencing the coupling alignment

- Easy maintenance

SHAFT SEALS

• Mechanical seals or

stuffing box glands

BRANCH POSITION

• A choice between the following positions:

delivery branch pointing upwards or to the

left or right (also adaptable at a later date)

BEARING ASSEMBLIES

• Drive-side axial bearing designed as paired angular- contact bearing.

Radial bearing designed as grooved bearing. Mechanical seals or stuffing box glands.

DRIVE

• Can be mounted on the

discharge or suction side

High-pressure pumps, HP series

ANDRITZ multi-stage high-pressure pumps from the HP series are used for various industrial applications such as water supply, irrigation, for hot and cold water circulation, firefighting, boiler feed and pressure boosting installations. They are suitable for transporting all clean or slightly dirty non-corrosive liquids up to a viscosity of 150 mm²/s (cSt). Under difficult suction conditions (low NPSH-available), the pump can be provided with an axial inlet for cavitation-reducing flow entry pattern into the first stage impeller.

ANDRITZ HP pump series

| Design: | multi-stage, high-pressure |

| Head: | up to 630 m |

| Flow rate: | up to 850 m³/h |

| Pressure: | up to 63 bar |

| Temperature: | up to 140° C |

| Speed: | up to 3,600 rpm |

| Efficiency: | up to 90% |

Product benefits

- Numerous hydraulic units per model size guarantee a design at the optimal operating point

- High efficiencies owing to optimized hydraulics

- Optimal adaptability to the medium to be pumped

- All wearing parts are renewable without additional work on the casing parts

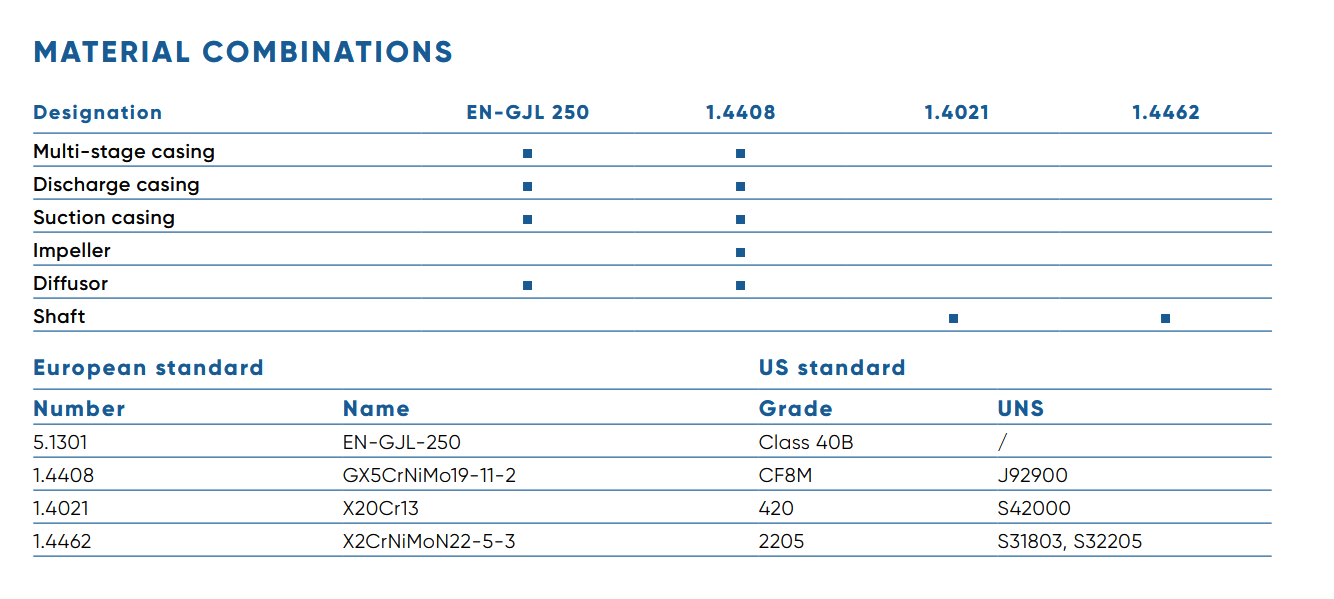

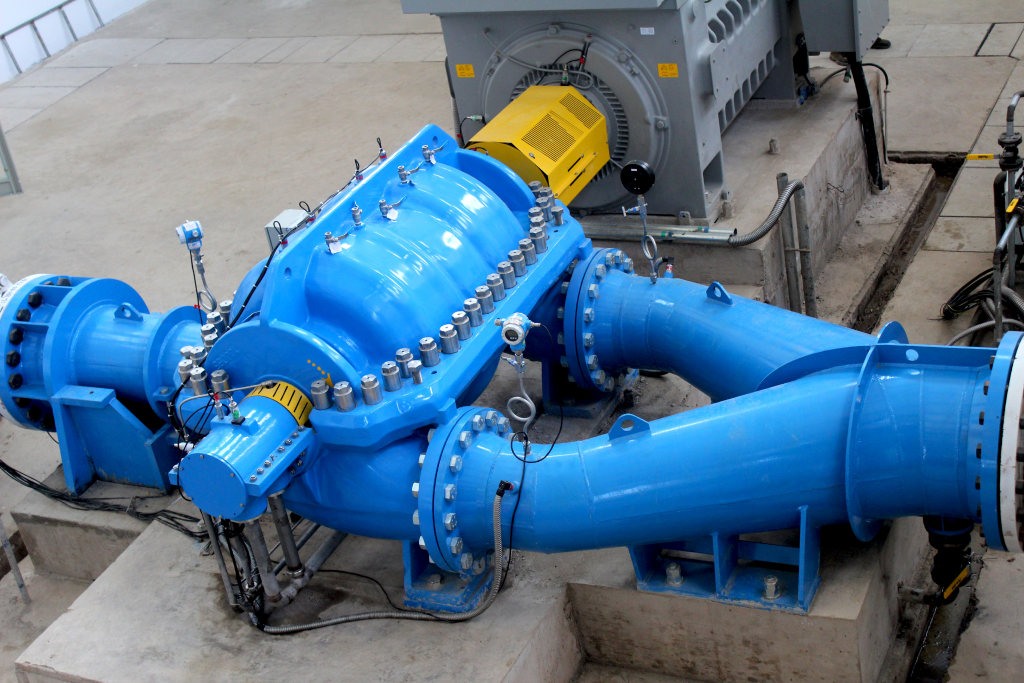

Multi-stage axial split case pump

The ANDRITZ multi-stage axial split case pump from the ASPM series has a multi-stage impeller arrangement that can be combined in different ways to fulfill various application needs. This is a highly engineered pump designed to customers’ specific requirements and at the same time based on a modular design concept. In a horizontal installation, the motor can be placed on the left or right or on both sides as twin drive. For a vertical installation, ANDRITZ multi-stage split case pumps, ASPM series, are available in a radial split case design with barrel casing.

The machine is used for continuous pumping of clean liquids in water supply projects, power station projects and desalination plants. Peak efficiencies and user-friendliness make this technology particularly effective, and in the axial split design maintenance-friendly at high heads.

Thanks to the excellent efficiency, which is above the industry average, and the speed-variable drive (order-related), this pump is characterized by its low energy consumption. The design is rigid, the machine is calculated and designed to withstand all load cases which might occur during the lifetime of the pump.

ANDRITZ ASPM pump series

| Design: | Multi-stage axial split case pumps with various impeller arrangements in single or double flow design |

| Head: | up to 1000 m |

| Flow rate: | up to 10 m³/s |

| Efficiency: | Highest efficiency available |

| Power: | up to 40 MW |

Product benefits

- Excellent efficiencies above industry average

- Very good NPSH values

- Low energy consumption

- Lower civil engineering costs due to lower NPSH requirements

- Less weight (radial split case/barrel casing)

- Cost-efficient (radial split case/barrel casing)

- Machine position provides an additional advantage for NPSH values (radial split case/barrel casing)

BEARING

• Roller and slide bearing with

and without external oil supply

BUSHING

• Replaceable and interchangeable for all stages

• Reduced leakage between

stages

LAST STAGE IMPELLER

• Specific impeller for double

suction design

• In case of double volute

compensation of radial load

STAGE IMPELLERS

• With excellent efficiency

1ST STAGE IMPELLERS

• Optionally suction impeller

for even better NPSH values

where needed

WEAR RINGS

• Replaceable and interchangeable wear rings for all stages

• Hydraulically optimized and

made of Al-Bronze

SHAFT

• Robust design drive shaft made

of high-quality stainless steel

SHAFT SEALING

• Single mechanical seal

• Other seal types on demand

EXTERNAL BEARING HOUSING

• For easy maintenance